Products

GLL non-glue without glue pocket spring unit production line mattress machine price

| Model | LR-PSA-GLL | ||

| Production capacity | 120-160 springs /min | ||

| Coiling head | Double wire coilling head | ||

| Working principle | Servo control | ||

| Spring shape | Standard versions:barrel and cylindrical | ||

| Air consumption | 0.33m³/min | ||

| Air pressure | 0.6-0.7mpa | ||

| Power consumption in total | 51KW | ||

| Power requirements | Voltage | 3AC380V | |

| Frequency | 50/60HZ | ||

| Input current | 71A | ||

| Cable section | 3*16m㎡+2*10m㎡ 3*6m㎡+2*4m㎡ |

||

| Working temperature | +5℃ to +35℃ | ||

| Weight | Approx.11000KG | ||

| Consumption Material Data | |||

| Non-woven fabric | |||

| Fabric density | 65-90g/㎡ | ||

| Fabric width | 3600-680mm | ||

| Inner dia. of fabric roll | Min.75mm | ||

| Outer dia. of fabric roll | Max.1000mm | ||

| Steel wire | |||

| Wire diameter | 1.6-2.3mm | ||

| Inner dia.of wire roll | Min.320mm | ||

| Outer dia.of wire roll | Max.1000mm | ||

| Acceptable weight of wire roll | Max.1000Kg | ||

| Working range(mm) | |||

| Wire Diameter | Spring Waist Diameter | Pocket Spring Height | |

| φ1.6-2.3 | φ55-75 | 120-250 | |

Environmentally friendly

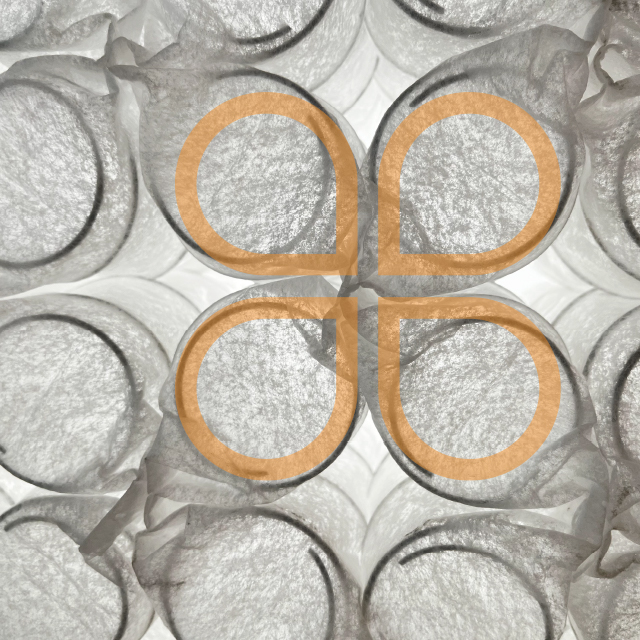

Innovative four-leaf clover non-glued bed core structure, human mechanics and green design concept

Non-glue mattress

Effectively avoid formaldehyde problems caused by glue, and not easy to loosen, the size of the bed core more stable

High support

Cost savings on consumables

Four-leaf clover structure makes the bed core support more stable

Saving material

Anti-collapse, anti-deformation, long-lasting and durable

1.Original technology

The equipment can realize fully automatic production of a variety of thicknesses of non-adhesive pocket spring units, undermining the traditional process, abandoning the adhesive bonding.

2.Environmentally friendly spring unit

The production process without any glue bonding, effectively eliminating the glue formaldehyde problem, green and healthy.

3.Mattress zoning

The machine can meet the functional requirements of mattress zoning. It can produce soft and hard zoning pocket spring unit.

4.Ultrasonic wave

The entire welding process is performed by ultrasonic wave. The welding between the spring rows are all performed by ultrasonic wave, which makes the structure of the spring unit stronger, the force of the spring pocket more uniform, and the durability better.

5.Four-leaf clover construction.

More stable support for the spring unit.