Pocket spring machine is a kind of machinery and equipment specially designed for manufacturing individual pocket spring mattresses. With the advancement of production technology, the pocket spring mattresses produced by it show a lot of performance superior to various other mattresses. Independent pocket spring mattress because it is supported by a number of independent pocket springs, not only has the advantages of high quietness, good air permeability, green and so on, but also has good resilience, stable support, durability and other characteristics. Therefore, the independent pocket spring mattress is popular in the mattress consumer market.

1.Pocket spring machine with the highest production speed: LR-PS-EV280

The machine, produced by Guangzhou Lianrou Machinery Equipment Co., Ltd, was first shown at the Cologne Germany Interzum, in 2023. It has a remarkable productivity of 280 springs/minute, which is significantly higher than pocket spring machines produced by other companies in the industry, which are known to produce a maximum of 160 springs/minute. Besides its industry-leading production efficiency, the machine has several benefits such as a unique E-shaped transfer structure design and a double-layer transfer cooling mechanism. These features reduce the machine's footprint, increase its spring heat-treatment capacity and support double wire feeding, enabling the production of zoned pocket springs for spring units, Consequently, mattresses can be manufactured using varying steel wire specifications, spring diameters, and heights. The production of pocket springs is characterized by stable performance and good quality. The machine efficiently integrates multiple advantages into a powerful single unit. In Europe, the machines are distributed by S-M-S schreiner machine service.

2.Ergonomic, individually curved and customized pocket spring production line: LR-PSLINE-DL

This machine is the only one on the market that produces a double-layered spring unit. The graduated support spring unit is the only one that can be personalised to meet the pressure curve of the human sleeping position.

Based on the collected data of height, weight, sleep pressure, etc., the corresponding spring support data is generated. The machine produces double-layer pocket springs according to the data parameters and can automatically adjust the height of the upper and lower springs to form a double-layer pocket spring string with gradual change of support, which is then assembled by the pocket spring assembly machine according to the length and width of the predetermined mattress to form a double-layer pocket spring unit. This personalized customization solution has a higher degree of fit and a better, more pronounced user experience. It meets the needs of single mattress customization and double mattress customization. In Europe, the machines are distributed by S-M-S schreiner machine service.

3.Pocket spring machine for electric beds:LR-PS-CL

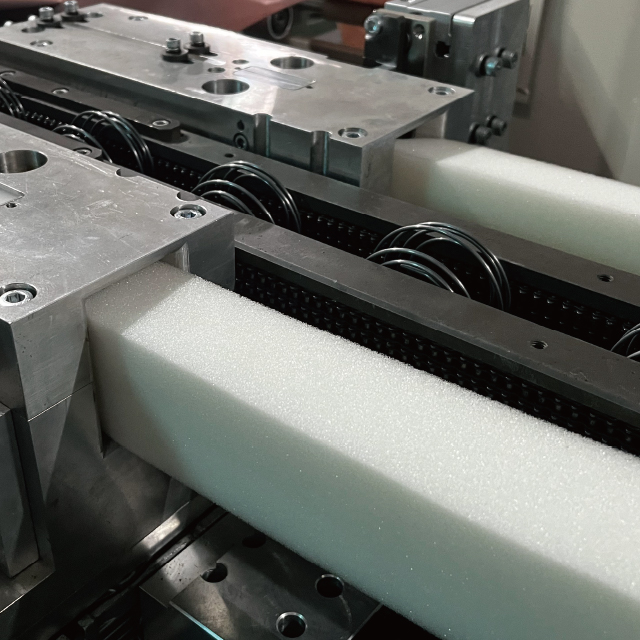

Composite comfort layer pocket spring machine, the production of pocket spring unit has a unique arc (or / \ type) welded structure. It can be used for electric beds or bent into any comfortable shape. It comes with its own foam comfort layer. The spring unit is produced with a foam comfort layer, and when the machine produces pocket springs, the comfort layer material is welded at both ends. When used as a material, after the spring unit is produced, there is no need to bond other comfort layer materials such as foams to make a complete mattress. This eliminates the need for subsequent mattress production processes, shortens the length of the production line and greatly improves production efficiency.

Due to the angled (or curved) arrangement of pocket springs, pocket spring units can be made with a third fewer springs than conventional spring units. There is also a softer effect when pocket springs are used in the production of regular mattresses. This reduces production costs and the weight of the mattress.

The machine is designed and manufactured by Guangzhou Lianrou Machinery Equipment Co., Ltd. and the patent for the spring unit structure is owned by the company. In Europe, the machines are distributed by S-M-S schreiner machine service

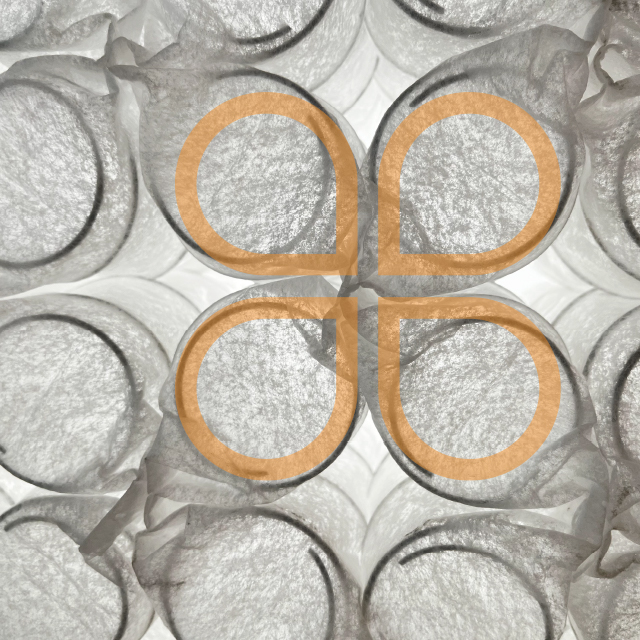

4.Environmentally friendly non-glue pocket spring assembly machine:LR-PSA-GLL

In 2023, Guangzhou Lianrou Machinery Equipment Co, Ltd launched the industry's first pocket spring assembly machine that can achieve fully automatic glue-free assembly of pocket spring units. The four-leaf clover structure non-adhesive spring unit produced by this machine breaks the traditional way of spring unit assembly, as the spring unit is assembled by ultrasonic welding, which makes the spring unit structure more stable and the spring unit products more environmentally friendly, reduces the material cost of the pocket spring unit production process, and reduces formaldehyde, benzene and other hazardous substances released from the glue. In Europe, the machines are distributed by S-M-S schreiner machine service.

The spring rows in the spring unit are also ultrasonically welded, giving the spring unit a stronger structure and a more uniform force on the spring pockets for better durability and environmental friendliness.

The machine also has the ability to produce soft and hard zoned spring units, with a choice of both single wire feed and double wire feed modes. If you choose double wire feed, you can use two sizes of steel wire for spring coiling and pocketing at the same time, so that the same spring unit has different softness and hardness in different areas. In Europe, the machines are distributed by S-M-S schreiner machine service

5.Pocket spring machine for producing soft and hard zoned mattress

The machine adopts double wire spring coiling technology. The wire frame simultaneously feeds two types of steel wires to the double wire spring coiler for spring coiling. During the production of pocket spring strings, the system automatically switches the coiling wire to spring coiling at the corresponding position according to the set parameters, thus achieving the variation of spring support force at different positions. After bonding the spring strings into spring units, the system can meet the demand of producing spring units with soft and hard zones, such as 5 zones and 7 zones.

The main representative manufacturers of this type of equipment are:

1.Guangzhou Lianrou Machinery's LR-PS-D220, with a maximum productivity of 220 springs per minute, is the highest productivity zoned pocket spring machine on the market.www.lianrou.com

2.Foshan Qilin mattress machinery’s GDZ9S-160DW has a maximum productivity of 160 springs per minute.

3.Foshan Yuantian mattress machinery’s YT-DZ-XD has a maximum productivity of 140 springs per minute.

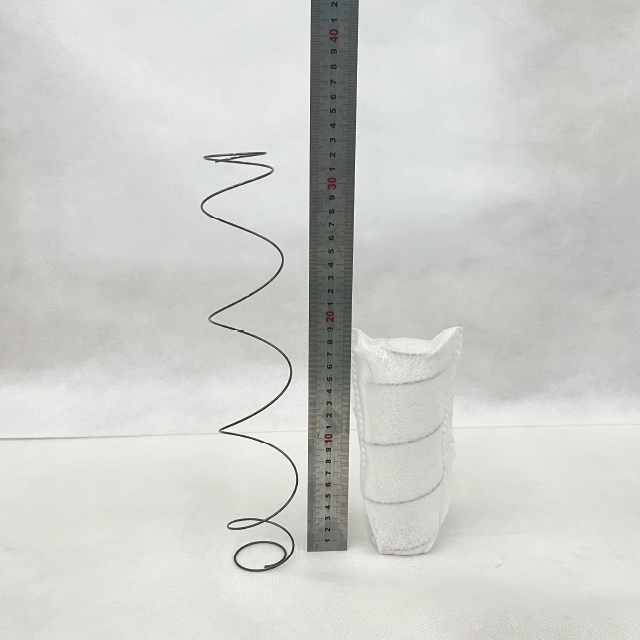

6.High compression ratio pocket spring machine: LR-PS-UMS/UMD

The high compression ratio technology developed by Guangzhou Lianrou Machinery Equipment Co., Ltd. enables the production of pocket springs with high compression and high elasticity characteristics. The spring compression ratio is up to 66% encapsulated in the bag, when compared with ordinary pocket springs, the high compression ratio springs have a stronger elastic support.

Lighter weight: When making spring units of the same size and thickness with the same support characteristics, it is possible to use finer steel wires to make spring units with high compression ratio technology to achieve better performance, thus reducing the weight of the spring units and making it easier to transport.

Lower cost: When producing the same performance of spring units, by using finer diameter steel wire for production, each spring unit (2000*1500mm) can save about 3KG weight of steel wire, saving material cost and transportation cost.

Guangzhou Lianrou Mattress Machine Company

Whatsapp: +8918926292610

Website: www.lianrou.com

Email: inquiry@lianrou.com

Post time: Aug-02-2023