Products

75P Semi-automatic manual control Pocket coil spring assembly mattress machines

| Model | LR-PSA-75P | |

| Production Capacity | 5-6 strings/minute | |

| Hot melt glue application system | Nordson(the USA) or Robatech (Switzerland) | |

| Capacity of glue tank | 7 kg | |

| Gluing method | Continuous gluing mode / Interrupted gluing mode |

|

| Control of assembling platform | Electronic control | |

| Possibility of assembling zoned tape | Possible | |

| Possibility of assembling zoning mattress | Possible | |

| Operation and Application | Feed the pocket spring strings manually | |

| Air Consumption | 0.1m³/min | |

| Air pressure | 0.6-0.7mpa | |

| Power consumption in total | 6.5kw | |

| Voltage | 3AC 380V | |

| Frequency | 50/60HZ | |

| Input current | 12A | |

| Cable section | 3*6mm²+2*4mm² | |

| Working temperature | +5℃ to + 35 ℃ | |

| Weight | Approx.2600kgs | |

| Consumption Material Data | ||

| Non-woven fabric data | ||

| Fabric density | 65-80g/m² | |

| Fabric width | 450-2200mm | |

| Inner dia.of fabric roll | Min.60mm | |

| Outer dia.of fabric roll | Max.600mm | |

| Hot Melt Glue Data | ||

| Shape | Pellet or pieces | |

| Viscosity | 125℃---6100cps | |

| 150℃---2300cps | ||

| 175℃---1100cps | ||

| Softening point | 85±5℃ | |

| Working Range | ||

| Option | Spring Waist Diameter (mm) | Pocket Spring Height (mm) |

| Option-01 | 45-75 | 100-300 |

| Option-02 | 30-75 | 60-240 |

Manual mode

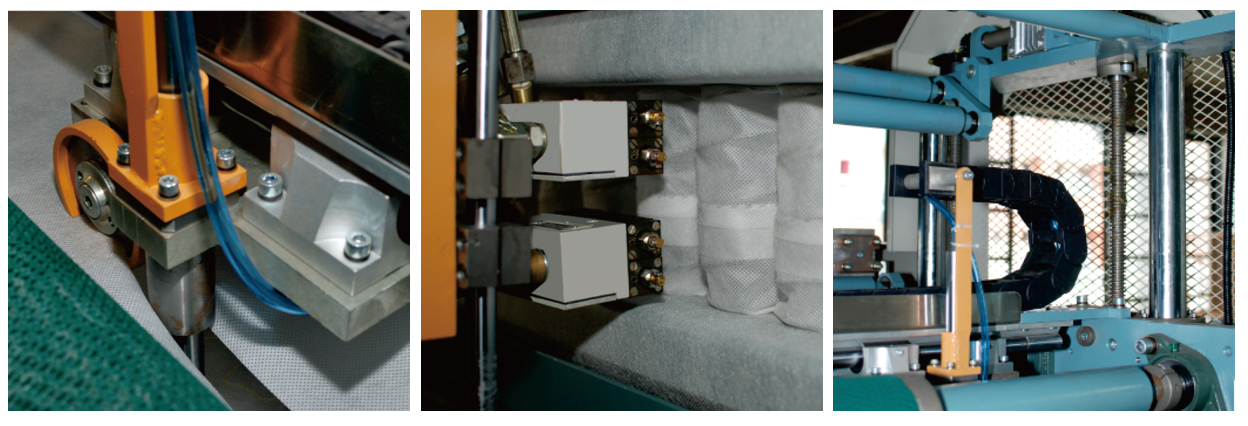

At the heart of the 75P is a state-of-the-art coil spring assembly system that can accommodate up to 5-6 strips per minute, ensuring that your production lines can keep pace with even the busiest of schedules. The manual control system allows you to fine-tune your production processes for optimal performance, while the advanced electronic control cutting device for the top and bottom fabric ensures precise and consistent cuts every time.

But the 75P is more than just a powerful and efficient mattress machine. With its independent hot melt jets, it can also help you achieve unparalleled levels of quality and consistency in every aspect of your manufacturing processes. Whether you're producing traditional coil spring mattresses or the latest in hybrid designs, the 75P is the ideal solution for automating your production lines and ensuring that your products meet the highest standards of quality and comfort.

So if you're looking for a reliable and efficient way to enhance your mattress manufacturing processes, look no further than the 75P Semi-automatic manual control Pocket coil spring assembly mattress machine. With its advanced features, cutting-edge design, and unparalleled performance, it's simply the best mattress machine on the market today.

FAQ

1) Do you have a global after-sales network?

Yes, we have a global after-sales network which includes remote online assistance.

2) What is your production efficiency compared to industry standards?

Our patented technologies make our production efficiency the highest in the industry.

3) Can we purchase spare parts for your machines?

Yes, we sell spare parts for our machines.

4) What is your lead time for production?

The lead time for production varies on the product and order quantity. We can provide more information on lead times for specific orders.