Products

99P 700 springs/min high speed easy operation pocket spring mattress assembly machine

| Model | LR-PSA-99P |

| Production Capacity | 700 springs/minute |

| Hot melt glue application system | Nordson(the USA) or Robatech (Switzerland) |

| Capacity of glue tank | 30kg |

| Gluing method | Spot spray/Continuous gluing mode / General economic mode |

| Possibility of assembling zoned tape | Possible |

| Possibility of assembling zoning mattress | Possible |

| Air Consumption | 0.15m³/min |

| Air pressure | 0.6-0.7mpa |

| Power consumption in total | 15kw |

| Voltage | 3AC 380V |

| Frequency | 50/60HZ |

| Input current | 25A |

| Cable section | 3*10mm²+2*6mm² |

| Working temperature | +5℃ to + 35 ℃ |

| Weight | Approx.4800kgs |

| Consumption Material Data: | |

| Non-woven fabric | |

| Fabric density | 55-80g/m² |

| Fabric width | 450-2200mm |

| Inner dia. of fabric roll | Min. 60mm |

| Outer dia. of fabric roll | Max. 600mm |

| Hot Melt Glue | |

| Shape | Pellet or pieces |

| Viscosity | 125℃---6100cps |

| 150℃---2300cps | |

| 175℃---1100cps | |

| Softening point | 85±5℃ |

| Working Range (mm) | |

| Spring Waist Diameter | 37-75mm |

| Pocket Spring Height | 55-250mm |

Specification Of 99P

1.Fully automatic intelligent bonding

High efficiency and stability, easy operation, higher bonding speed in the industry, easy operation of the control interface and good equipment stability.

2.CE Standard.

Tested and certified by SGS, in accordance with CE standard.

3.An optional cabinet temperature control box

An optional cabinet temperature control box is available to ensure adhesive stability, consistent bonding results, and cleanliness of the bonding process.

4.Standard configuration for large capacity adhesive melter.

The 30kg adhesive melter capacity is standardized to ensure stable operation over a long period of time.

5.Meet the "three dragged by one"

Three pocket spring machines and one pocket spring assembly machine to form a production line

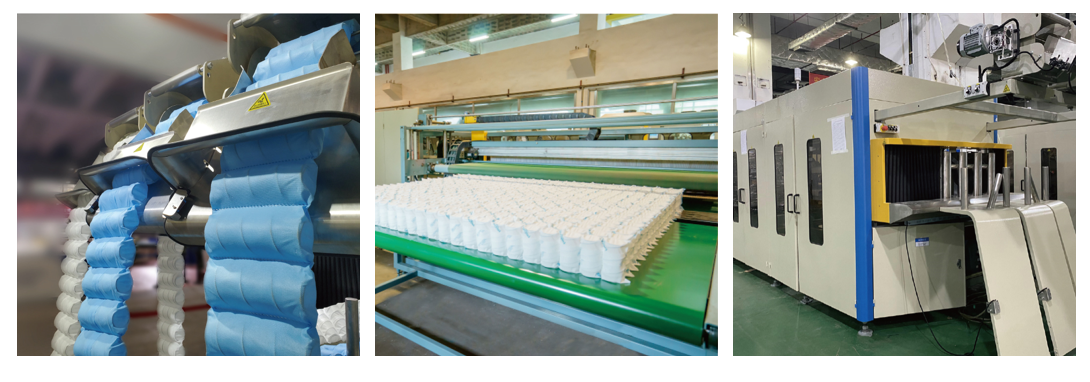

Heat-treatment and spring rebound

Pocket spring assembly machine (PSA99P) can matched with three pocket spring machines form a production line

Orderly feeding between the channels

Back and forth glue spraying, high assembling efficiency

Choose whether to use top and bottom fabrics or not

The PSA99P can also be matched with three pocket spring machines, forming a complete production line for pocket spring mattresses. With its orderly feeding system and back and forth glue spraying, the machine is designed to maximize efficiency, while ensuring high-quality end products. The precise assembly process takes the guesswork out of production, delivering perfect, uniform results every time.

Stable spring production process and good product quality

Perhaps one of the best things about the PSA99P is how easy it is to operate. Its intuitive design and user-friendly interface make it a breeze to use, even for those new to the industry. Operators can quickly get up to speed with the machine's capabilities, and start producing top-quality mattresses in no time at all.

Overall, the PSA99P is a game-changer in the world of manufacturing. Its impressive speed, stability, and ease of operation make it a top choice for companies looking to stay competitive in today's fast-paced market. So if you're looking for a way to improve production and produce high-quality mattresses at scale, look no further than the PSA99P pocket spring mattress assembly machine.

Keywords:PSA99P, pocket spring machines, production line, mattresses, feeding system, glue spraying, efficiency, high-quality, assembly process, easy to operate, intuitive design.