Products

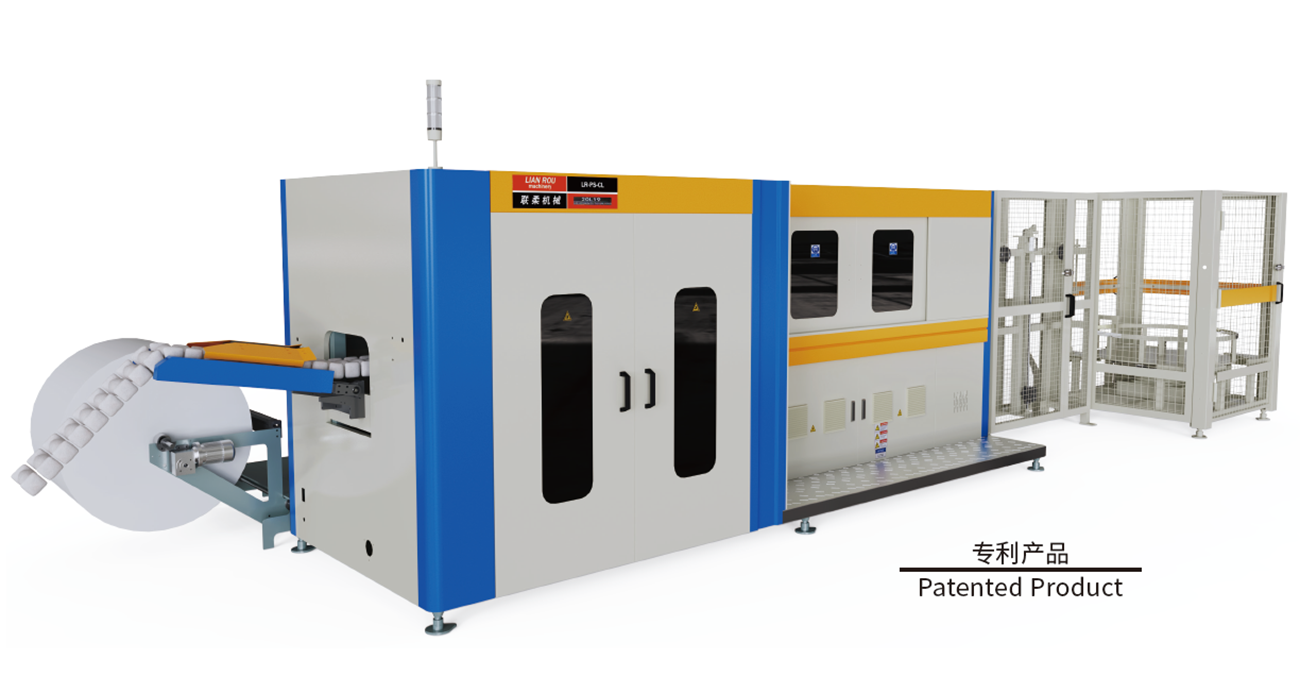

CL Compound comfort layer Cloud china spring mattress making machine

| Machine Features | |||

| Model | LR-PS-CL | ||

| Production capacity | 80 Springs/min. | ||

| Coiling head | Single servo coiling head | ||

| Working principle | Servo control | ||

| Spring shape | C shape,Y shape,Olive shape | ||

| Air consumption | 0.65m3/min. | ||

| Air pressure | 0.6-0.7mpa | ||

| Power consumption in total | 48KW | ||

| Power requirements | Voltage | 3AC 380V | |

| Frequency | 50/60HZ | ||

| Input current | 75A | ||

| Cable section | 3*25mm2+2*16mm2 | ||

| Working temperature | +5℃+35℃ | ||

| Weight | Approx.5500Kg | ||

| Consumption Material Date | |||

| Non-woven fabric | |||

| Fabric density | 65-75g/m2 | ||

| Fabric width | 700-760mm | ||

| Inner dia.of fabric roll | 75mm | ||

| Outer dia.of fabric roll | Max.1000mm | ||

| Steel wire | |||

| Wire diameter | 1.5-2.2mm | ||

| Inner dia.of wire roll | Min.320mm | ||

| Outer dia.of wire roll | Max.1000mm | ||

| Acceptable weight of wire roll | Max.1000Kg | ||

| Foam size of layer | |||

| Foam size | 50+50mm | ||

| Working Range(mm) | |||

| Wire Diameter | Spring Waist Diameter | Pocket Spring Height | |

| Option1 | φ1.5-1.8mm | Φ60-65mm | 200mm |

| Option2 | φ1.8-2.2mm | Φ65-70mm | 220mm |

1.Complete mattress

The comfort layer and pocket springs are produced in one operation, which simplifies the mattress production process and reduces the length of the production line. When the equipment produces pocket springs, the comfort layer material is welded to both ends of the pocket springs, and after the spring units are formed, there is no need to bond other comfort layer materials, such as sponge, to produce a complete mattress.

2.Different structure.

The machine can produce unique structure of spring unit, used for electric beds, which can be bent at will, with spring units related patents, the spring arrangement of "人" and ") (" shape structure. The spring arrangement is curved or inclined, with corresponding space for the mattress to bend, widely used in electric beds, electric sofas, and can be adjusted to any shape.

3.Saving of raw materials.

The production of pocket spring bed core can save one third of the spring compared to the conventional bed core; when used in ordinary mattresses, there is a softer effect.

Heat-treatment and spring rebound

Introducing our latest innovation in bedding materials: the innovative spring core structure that promises to revolutionize the way we experience comfort in bed. This new comfort layer is designed to address the common issues that people have with traditional bedding materials, such as sagging, flattening, and inadequate support. With its unique construction, the spring core structure is not only a replacement for existing comfort layers but is also available for adjustable beds.

Stable spring production process and good product quality

One of the key features of this innovative product is the combination of the comfort layer and pocket spring produced in a single process. By doing this, we have shortened the production line, making it more efficient and reducing the overall cost of production. This makes it possible for our customers to enjoy a high-quality product at an affordable price.

Another advantage of the innovative spring core structure is that it is available in different kinds of pocket springs. This means that our customers can choose the type of pocket spring that suits their individual comfort and support needs. For example, some people prefer a softer touch, while others prefer a firmer feel. Whatever your preference, we’ve got you covered!

What sets our innovative spring core structure apart from other bedding materials is its unique construction. The core of the product is made up of individually wrapped pocket springs, which are then surrounded by layers of foam and fabric. This combination of materials provides excellent support, regardless of your sleeping position, while also ensuring that you stay cool and comfortable all night long.

One of the benefits of the spring core structure is that it provides excellent pressure relief. The individually wrapped pocket springs are designed to move independently of one another, providing targeted support where you need it the most. This helps to alleviate pressure points, providing you with a more restful sleep experience.

Furthermore, the innovative spring core structure is versatile and can be used in adjustable beds. This makes it an ideal choice for people who suffer from back pain, as an adjustable bed can help to alleviate pressure on the spine.

In conclusion, if you are looking for a high-quality, affordable, and versatile bedding product that is designed to provide excellent support and comfort, then the innovative spring core structure is the perfect choice for you. With its unique construction, excellent pressure relief, and versatile design, this product is sure to provide you with many years of restful nights and peaceful sleep.

Welcome to contrat us

In terms of price, we have a special quotation sheet for each machine. At the same time, we can also provide professional mattress machinery solutions and quotations according to your manufacturing needs.

If you need more information about mattress pocket spring machine, please leave us a message, or contact our sales representative.

| Machine Features | |||

| Model | LR-PS-CL | ||

| Production capacity | 80 Springs/min. | ||

| Coiling head | Single servo coiling head | ||

| Working principle | Servo control | ||

| Spring shape | C shape,Y shape,Olive shape | ||

| Air consumption | 0.65m3/min. | ||

| Air pressure | 0.6-0.7mpa | ||

| Power consumption in total | 48KW | ||

| Power requirements | Voltage | 3AC 380V | |

| Frequency | 50/60HZ | ||

| Input current | 75A | ||

| Cable section | 3*25mm2+2*16mm2 | ||

| Working temperature | +5℃+35℃ | ||

| Weight | Approx.5500Kg | ||

| Consumption Material Date | |||

| Non-woven fabric | |||

| Fabric density | 65-75g/m2 | ||

| Fabric width | 700-760mm | ||

| Inner dia.of fabric roll | 75mm | ||

| Outer dia.of fabric roll | Max.1000mm | ||

| Steel wire | |||

| Wire diameter | 1.5-2.2mm | ||

| Inner dia.of wire roll | Min.320mm | ||

| Outer dia.of wire roll | Max.1000mm | ||

| Acceptable weight of wire roll | Max.1000Kg | ||

| Foam size of layer | |||

| Foam size | 50+50mm | ||

| Working Range(mm) | |||

| Wire Diameter | Spring Waist Diameter | Pocket Spring Height | |

| Option1 | φ1.5-1.8mm | Φ60-65mm | 200mm |

| Option2 | φ1.8-2.2mm | Φ65-70mm | 220mm |